Tobacco Fixture Materials: Wood Metal Acrylic Pros and Cons

- Design drivers shaping tobacco fixtures

- Retail goals and user intent

- Operational constraints: space, maintenance, and compliance

- Brand and visual merchandising priorities

- Material-by-material analysis: wood, metal, acrylic

- Wood: aesthetics, customization, and perceived value

- Metal: strength, security, longevity

- Acrylic (PMMA): clarity and lighting flexibility

- Comparative table: quick reference

- Security, compliance and sustainability considerations

- Securing high-value tobacco products

- Fire safety and material compliance

- Sustainability and lifecycle costs

- Choosing the right material for your tobacco fixtures: scenarios and recommendations

- High-security, high-traffic convenience or tobacco shop

- High Quality boutique or branded dispensary environment

- Budget-conscious pop-up or temporary displays

- Modular dispensary fixtures for evolving assortments

- Fabrication, finish and supplier considerations

- Precision fabrication and tolerances

- Finishes, coatings and anti-theft detailing

- Vendor selection checklist

- Ouyee: partner profile and manufacturing strengths

- Practical checklist: specifying tobacco fixtures

- Core specification items

- Installation and lifecycle planning

- Cost vs. value analysis

- FAQs

- 1. Which material offers the best theft protection for tobacco products?

- 2. Is acrylic safe to use in enclosed tobacco display cabinets?

- 3. How do I reduce maintenance for wooden tobacco displays?

- 4. Can I mix materials in a single fixture?

- 5. How important is manufacturer capability when choosing fixtures?

- 6. Are there sustainable options for tobacco fixtures?

- Conclusion & next steps

Choosing the right material for tobacco fixtures affects aesthetics, security, compliance, lifecycle cost, and shopper experience. This article provides a practical, evidence-based comparison of wood, metal, and acrylic for tobacco display racks and dispensary fixtures, explaining performance trade-offs, maintenance expectations, safety implications, and real-world selection criteria useful to retail buyers, visual merchandisers, and fixture specifiers. The guidance conforms to retail-display best practices and industry material data to help you spec tobacco fixtures that balance brand, cost, and regulatory needs.

Design drivers shaping tobacco fixtures

Retail goals and user intent

Before selecting materials for tobacco fixtures, clarify the core retail goals: product security, merchandising visibility, brand impression, durability under daily use, and ease of reconfiguration. Customers searching for tobacco fixtures are typically solving operational problems—secure storage of high-value products, theft deterrence, attractive presentation for brand-driven SKUs, and long-term ROI through durable displays. Decisions should align with those outcomes.

Operational constraints: space, maintenance, and compliance

Fixtures must fit the store footprint, comply with local regulations (age-restricted display rules, fire codes), and match staff maintenance capacity. For fire- and safety-related considerations, consult standards and guidance such as the National Fire Protection Association (NFPA) and local codes. Material choice influences cleaning regimes, required fixtures anchors, and permitted lighting or enclosed cabinetry.

Brand and visual merchandising priorities

A retailer’s brand—High Quality boutique, value-driven convenience, or dispensary-grade—dictates finish and feel. Wood conveys warmth and luxury; metal gives a high-security, industrial look; acrylic maximizes product visibility and illumination. Align material selection with the shopper experience you want to create.

Material-by-material analysis: wood, metal, acrylic

Wood: aesthetics, customization, and perceived value

Wood and engineered wood (plywood, MDF, hardwood veneers) are chosen for warmth and custom craftsmanship. Wood can be routed, stained, veneered, or painted to match brand identity and is forgiving for in-store repairs. However, wood is typically more combustible than metal or some plastics and may require fire-retardant treatments where local code mandates. For general material properties, see the wood overview at Wikipedia.

Metal: strength, security, longevity

Metal fixtures—commonly stainless steel, aluminum, or powder-coated steel—excel in structural strength, security (lockable cabinets, integrated locks), and longevity in high-traffic environments. Metals are non-porous, easier to sanitize, and resist many forms of wear. Stainless steel offers corrosion resistance; aluminum reduces weight for modular systems. For properties and grades, refer to stainless steel and aluminium references.

Acrylic (PMMA): clarity and lighting flexibility

Acrylic (polymethyl methacrylate) brings crystal-clear transparency, lightweight construction, and superior light transmission for illuminated tobacco display cases and e-cigarette showcases. Acrylic is easy to form into curved shelves or domes and integrates with LED lighting to enhance SKU visibility. Note acrylic’s flammability and scratch sensitivity compared with glass; consult material properties at PMMA (acrylic).

Comparative table: quick reference

| Material | Pros | Cons | Typical Security | Maintenance |

|---|---|---|---|---|

| Wood / Engineered wood | Warm aesthetics, custom finishes, easy onsite repairs | Can be combustible, prone to scratches/wear, variable durability | Medium (can be reinforced/lockable) | Periodic refinishing, dusting; sensitive to moisture |

| Metal (stainless, powder-coated) | High strength, durable, tamper-resistant, easy to sanitize | Can look industrial/cold, heavier, higher initial cost for High Quality alloys | High (secure cabinets, integrated locks) | Low; occasional polishing and rust checks for non-stainless |

| Acrylic (PMMA) | High clarity, lightweight, excellent for illumination and modern look | Scratch-prone, can crack under impact, combustible at high heat | Low–Medium (requires metal framing/locks for security) | Wipes with non-abrasive cleaners; scratch repair can be difficult |

Notes: The table provides a qualitative comparison for typical retail tobacco fixtures. Specific performance depends on material grade, fabrication, and integration of locks or glazing. For regulatory safety considerations related to flammability, consult NFPA.

Security, compliance and sustainability considerations

Securing high-value tobacco products

Tobacco fixtures often store high-value, age-restricted products that attract theft. Metal cabinets with integrated locks and reinforced glazing are the industry standard for security. Acrylic may be used for visibility but should be combined with metal lock housings or security glass to meet loss-prevention requirements. Consider UL-listed locks and industry best practices for anchors and mounts to prevent grab-and-run incidents.

Fire safety and material compliance

Materials’ flammability can affect compliance. Wood products may require fire-retardant treatments or limits under local building codes. Acrylic is combustible and may produce smoke under high heat; metals are non-combustible but will conduct heat. Check local fire codes and consult authorities such as the NFPA for applicable requirements. When lighting or heat sources are integrated (LEDs, transformers), ensure clearances and wiring meet electrical codes.

Sustainability and lifecycle costs

Environmental concerns influence procurement. Solid wood from certified sources (e.g., FSC) can be a sustainable choice; engineered wood may off-gas formaldehyde unless low-VOC adhesives are used. Metal recycling rates are high—steel and aluminum are commonly recycled—reducing lifecycle impact. Acrylic is a petroleum-derived plastic with more limited recycling streams. Lifecycle cost analysis should weigh initial cost, expected lifespan, repairability, and disposal/recycling options.

Choosing the right material for your tobacco fixtures: scenarios and recommendations

High-security, high-traffic convenience or tobacco shop

Recommendation: Metal-dominant fixtures with lockable stainless-steel cabinets, tempered glass or thick acrylic with metal framing. Rationale: durability, low maintenance, superior theft resistance. Add modular components for easy SKU rotation. Example features: built-in locks, alarm contacts, back-counters that reduce employee reach-around theft.

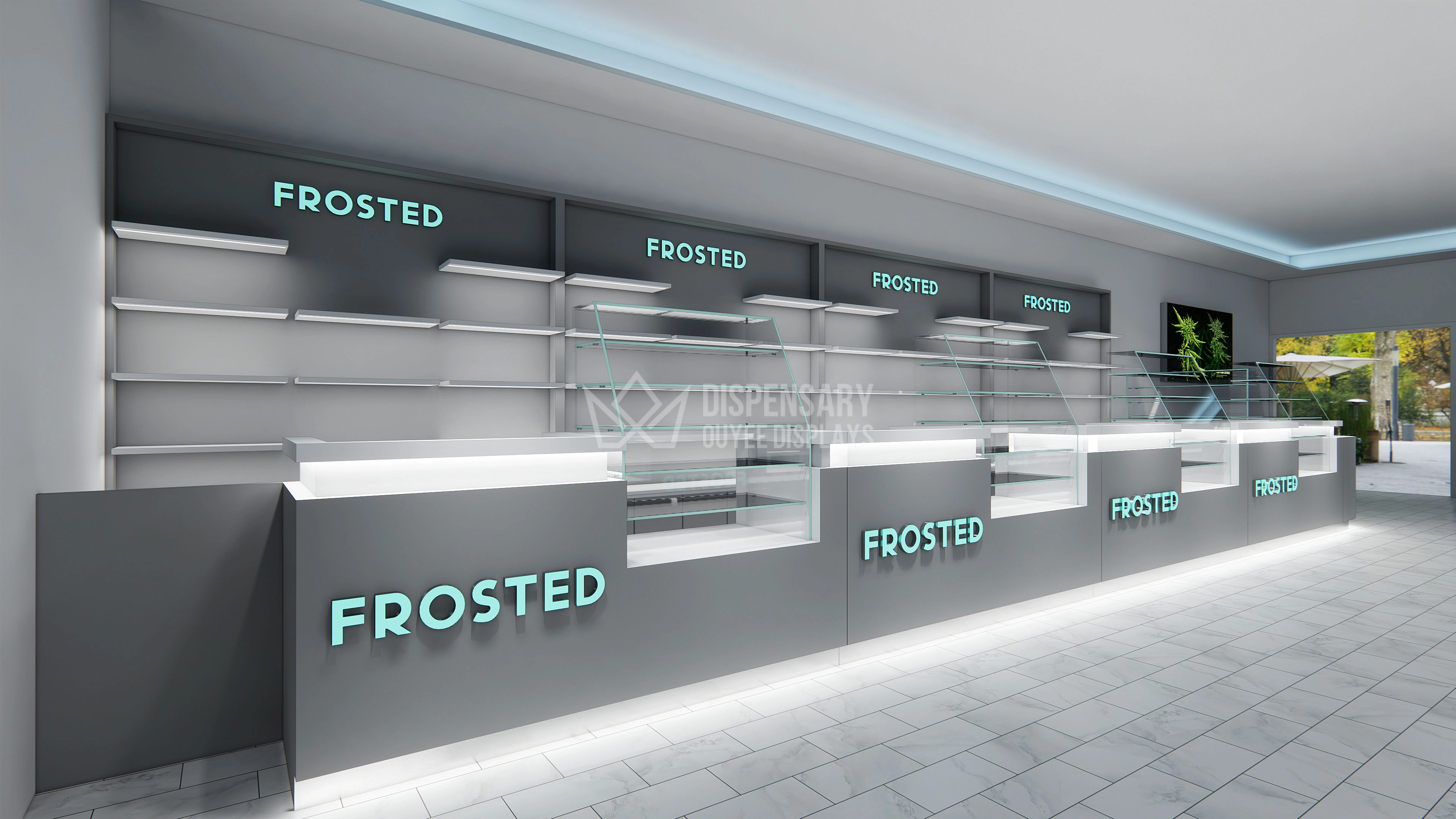

High Quality boutique or branded dispensary environment

Recommendation: Hybrid fixtures — wood veneer casework for warmth with integrated metal lockboxes and acrylic display elements for visibility. Rationale: Wood provides brand-appropriate aesthetics; metal and secure glazing preserve product safety. Consider high-quality veneer or sustainably sourced hardwood to align with brand values.

Budget-conscious pop-up or temporary displays

Recommendation: Lightweight aluminum or engineered wood with acrylic panels. Rationale: Lower cost, portability, and visual clarity. Ensure lockable trays or temporary security enclosures for overnight protection.

Modular dispensary fixtures for evolving assortments

Recommendation: Powder-coated steel frames with interchangeable acrylic shelves and modular inserts. Rationale: Steel provides backbone strength; acrylic and MDF shelving can be swapped as assortment changes, supporting reconfiguration and seasonal merchandising.

Fabrication, finish and supplier considerations

Precision fabrication and tolerances

High-quality tobacco fixtures require accurate fabrication to ensure secure locks, flush glazing, and reliable hinges or sliders. Suppliers using CNC machining centers and controlled finishing processes reduce scrap and improve repeatability. Tolerances influence door alignment for lock reliability and smoke/odor sealing in enclosed cabinets.

Finishes, coatings and anti-theft detailing

Powder-coating on metal increases scratch resistance. Hard-wax oil or catalyzed finishes on wood enhance water resistance and wear life. For acrylic, anti-scratch coatings (hardcoat treatments) boost durability. Integrated anti-theft hardware—tamper-resistant fasteners, concealed hinges, and lock housings—improve loss prevention.

Vendor selection checklist

- Facility capability: in-house machining, finishing, and assembly (reduces coordination errors)

- Quality systems: ISO or documented QC processes for repeatable builds

- Material sourcing transparency: FSC certification, alloy specs, acrylic grade

- Security expertise: experience in lock integration, alarm-ready fittings

- After-sales support: spare parts, maintenance guidance, replacement panels

Ouyee: partner profile and manufacturing strengths

Ouyee Dispensary Displays is your trusted partner for providing comprehensive, custom-designed display solutions for your cannabis retail store and allied markets. Our state-of-the-art 180,000-square-foot facility in Guangzhou, China, has been designing and producing high-end functional display cabinets for over 25 years. From cannabis dispensaries to pharmacy showcases, tobacco display racks, and e-cigarette showcases, Ouyee has earned the trust of clients across sectors by delivering precision-crafted fixtures.

Technical strengths and competitive differentiators:

- Advanced manufacturing: German-made CNC automation machining centers for tight tolerances and consistent quality.

- Custom engineering: In-house design capability to integrate locks, lighting, and modular systems that meet retail and compliance needs.

- Product range: cannabis display cases, CBD displays, dispensary displays, dispensary fixtures, smoke shop display cases, and Weed Dispensary display solutions designed for aesthetics, security, and usability.

- Quality focus: emphasis on durable finishes, security integrations, and post-sale support for spare parts and maintenance.

- Vision: to become the world’s leading cannabis dispensary display manufacturer.

Learn more or request a custom consultation at https://www.ouyeedispensary.com/.

Practical checklist: specifying tobacco fixtures

Core specification items

When preparing a spec package or RFQ, include: exact dimensions, product load per shelf, lock type and placement, lighting type and transformer location, finish samples, anchoring details, and warranty terms. Specify regulatory constraints (e.g., local fire-code requirements) and security targets (e.g., retail loss-prevention KPIs).

Installation and lifecycle planning

Plan for installation access (doorways, elevator size), on-site finishing needs, and spare-part provisioning. Agree on lead times, protective packing for transit, and on-site training for staff on locks and maintenance.

Cost vs. value analysis

Compare initial material cost with expected lifespan and resale/repairability. Metal fixtures can have higher upfront cost but deliver lower lifetime maintenance. Wood offers design flexibility but may require refurbishing. Acrylic provides visual impact but must be protected against scratches and impact.

FAQs

1. Which material offers the best theft protection for tobacco products?

Metal fixtures (stainless or powder-coated steel) with integrated locks offer the highest intrinsic theft protection. Combining metal cabinets with reinforced glazing or acrylic that is secured into a metal frame balances visibility and security.

2. Is acrylic safe to use in enclosed tobacco display cabinets?

Acrylic is safe for visibility but is more combustible than metal and can scratch easily. For enclosed cabinets, use acrylic only when combined with proper ventilation, fire-code-compliant lighting, and metal structural framing or lock housings. Consult local fire codes and NFPA guidance.

3. How do I reduce maintenance for wooden tobacco displays?

Choose durable veneers or high-quality finishes (e.g., catalyzed varnishes), avoid direct sunlight exposure that accelerates fading, and schedule periodic cleaning and spot refinishing. Use water-resistant treatments in humid environments.

4. Can I mix materials in a single fixture?

Yes. Hybrid fixtures (wood veneers for exterior aesthetic, metal frames for structural security, acrylic for display zones) are common and often provide the best balance of brand, security, and cost-effectiveness.

5. How important is manufacturer capability when choosing fixtures?

Very important. Manufacturers with precision CNC equipment, integrated finishing lines, and experience with lock and lighting integrations reduce risk, ensure consistent quality, and shorten lead times. Suppliers that provide clear material specs, test reports, and installation support add measurable value.

6. Are there sustainable options for tobacco fixtures?

Yes. Look for FSC-certified wood, high-recycled-content metals (steel, aluminum), and manufacturers that practice responsible waste management and low-VOC finishing. Metal frames are generally more recyclable at end-of-life than acrylic.

Conclusion & next steps

Selecting materials for tobacco fixtures requires balancing security, aesthetics, maintenance, compliance, and total cost of ownership. Metal provides the strongest security and durability, wood offers High Quality aesthetics and customization, and acrylic maximizes visual clarity and lighting effects. Hybrid solutions often deliver the best combined outcome. When sourcing fixtures, prioritize manufacturers with proven fabrication capabilities, thoughtful design for loss prevention, and after-sales support.

For tailored, high-quality tobacco display racks, smoke shop display cases, and dispensary fixtures, Ouyee Dispensary Displays offers end-to-end design and manufacturing backed by a 180,000-square-foot production facility and 25+ years of experience. Contact Ouyee for a custom consultation or to view product examples: https://www.ouyeedispensary.com/.

Security-Conscious Display Ideas for High-Value Cannabis Items

Top cannabis cabinet Manufacturers and Suppliers

Top display case flower cannabis Manufacturers and Suppliers

Custom Custom cannabis Displays Manufacturers and Suppliers

Turnkey Solution Modern Cannabis Dispensary Design Companies

Can I use this display for vape and tobacco items too?

Yes, our systems are adaptable for vape pens, tobacco pipes, oils, CBD tinctures, and more.

What’s the average lead time for a full turnkey dispensary setup?

Production takes 4–6 weeks depending on order size. Sea shipping typically adds another 4–6 weeks.

Professional 3D Design Tempered Glass Tobacco Fixture Manufacturer

How are the fixtures shipped?

All units are knockdown-assembled and foam-padded inside wooden crates, suitable for export.

Trendy Custom E Cigarette Display Rack Cbd Shop Displays Solutions

What type of lighting is used?

We use energy-efficient LED strips and integrated spotlights to enhance product visibility and reduce energy costs.

Custom 3D Design Tempered Glass CBD Product Displays Solutions

How do you ensure safety during shipping?

We use multi-layer foam and wooden crates, with full knock-down packaging to prevent breakage.

Customized Wholesale Hookah Lounge Furniture For Sale

Elevate your lounge experience with our premium customized hookah lounge furniture, designed for modern aesthetics and maximum comfort. With a strong emphasis on privacy, atmosphere, and luxury, our modular sofa systems, LED accents, and functional shisha setups are tailored to transform any space into a high-end smoking destination. Ideal for lounges, nightclubs, or upscale cafes seeking a bold, unified interior identity.

Wooden Marihuana Dispensary Shelves Cannabis Display Case Manufacturer

Premium wood display cases for cannabis dispensaries, combining natural aesthetics with secure, functional shelving solutions.

Custom Modern Minimalist LED Light Strips Good Display of Smoke Shop

Modern LED-lit custom display cases tailored for smoke shops, combining sleek aesthetics with practical storage and high visibility for merchandise.

Tempered Glass Vape Shop Fixtures CBD Retail Displays Solutions

High-end CBD retail display fixtures with tempered glass and modular cabinets. Designed for vape shops prioritizing sleek style, product visibility, and premium customer experience.

Ouyee Dispensary

Ouyee Dispensary

Ouyee Dispensary

Ouyee Dispensary